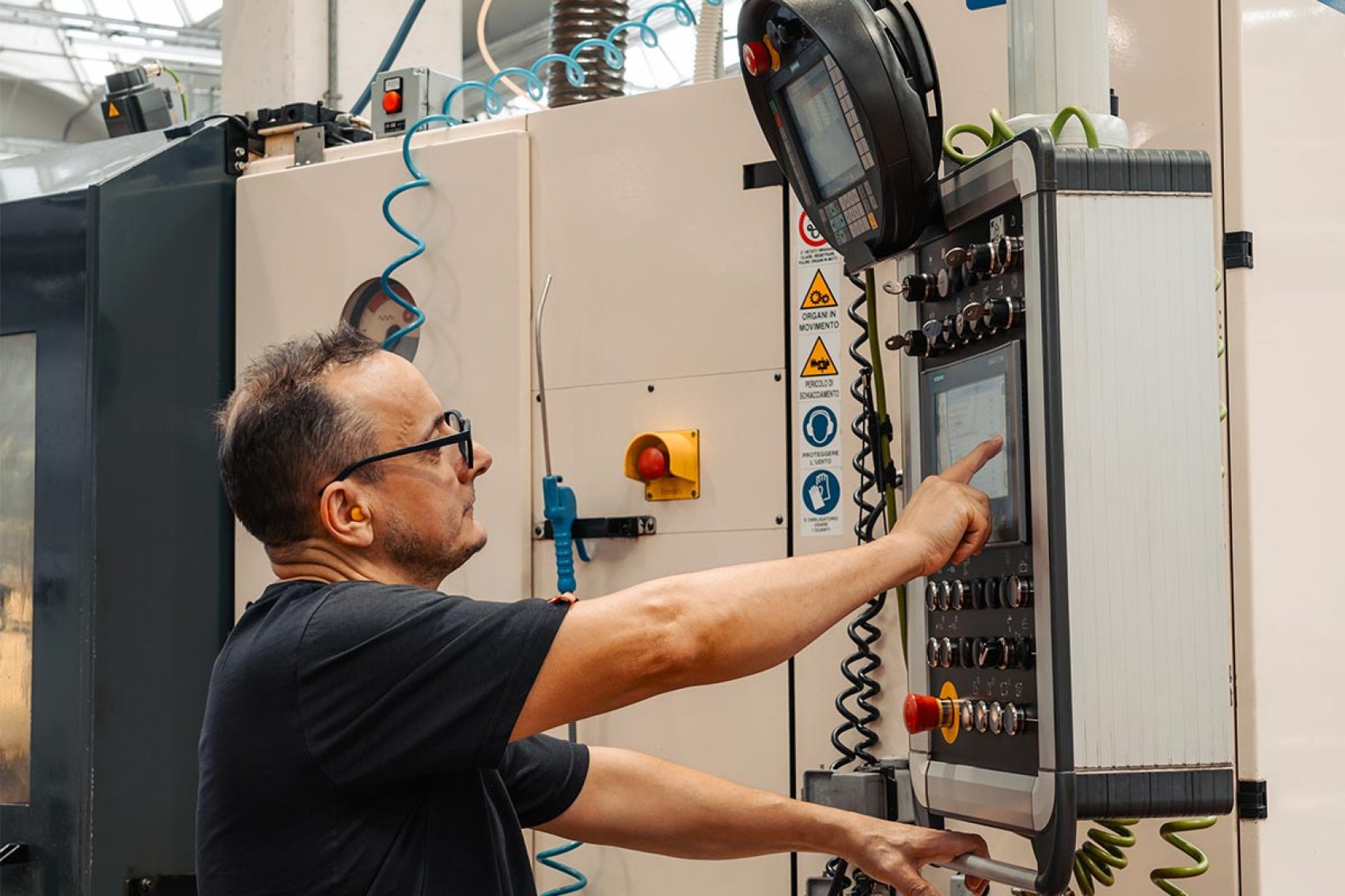

At the heart of CNC turning are Computer Numerical Control (CNC) machines—systems capable of managing tool movements with the utmost precision, following detailed instructions generated by CAD/CAM programming software. This technology allows for the production of complex shapes and intricate geometries while maintaining extremely tight tolerances, which are essential in sectors such as automotive, hydraulics, and medical component manufacturing.

The Advantages of CNC Turning

Repeatability is one of the most significant advantages of CNC turning for metal small parts. Once the machining program is set up, each part produced is identical to the previous one, with minimal dimensional variation. This is a critical requirement for industries like automotive, hydraulics, and precision mechanics, where tight tolerances are non-negotiable.

Another key advantage of CNC turning is production speed. Modern CNC lathes can operate at significantly higher spindle speeds and feed rates than traditional machines, drastically reducing cycle times. Moreover, automatic operation allows production to continue during night shifts and weekends, boosting output capacity.

The production flexibility of a CNC turning shop enables a quick switch from one part type to another by simply loading a different machining program. This versatility is especially beneficial for variable batch production and rapid prototyping.

Complex Components and Tight Tolerances

CNC lathes excel in the machining of geometrically complex components that would be difficult—or even impossible—to produce manually. Asymmetrical profiles, multi-start threads, helical grooves, and curved surfaces can be manufactured consistently and with absolute precision.

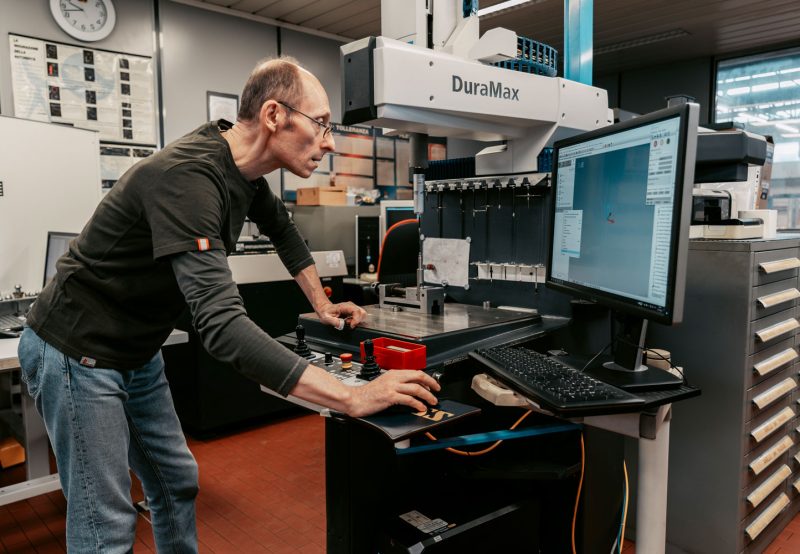

Typical dimensional tolerances in CNC turning are around ±0.05 mm for standard operations, but can reach ±0.02 mm on high-precision machines under controlled conditions. These results are made possible through the integration of high-end mechanical systems, advanced numerical controls, and next-generation cutting tools.

Automatic tool wear compensation systems allow required tolerances to be maintained even over extended production runs, eliminating the need for frequent manual adjustments.

Optimizing Production Cycles in CNC Turning

Production cycle optimization through CNC turning relies on multiple technological factors. CAM software enables virtual simulation of the machining process, identifying optimal tool paths and cutting parameters before actual production begins.

Combining multiple operations in a single setup reduces setup times and eliminates repositioning errors. Multitasking CNC lathes can perform turning, milling, and drilling on a single machine, drastically shortening lead times and improving overall accuracy.

Adaptive monitoring systems automatically adjust cutting speeds and feed rates based on real-time machining conditions, continuously optimizing performance and preventing tool breakage that could compromise the entire production batch.

Sarbo: CNC Turning at Its Best

Sarbo is a CNC turning shop that responds swiftly to market needs and customer specifications, offering modern, quality-driven manufacturing. We ensure precision, scalability, and continuous production flow. Bar-turned parts are subject to strict controls via the OEE (Overall Equipment Effectiveness) system and are manufactured based on customer drawings.

Our CNC turning processes are developed according to Lean Production and Six Sigma principles, aiming to reduce waste and optimize costs.

In our CNC turning department, we machine a wide range of materials including brass alloys, aluminum alloys, bronze, stainless steels, free-cutting steels, and alloy steels. Raw materials are sourced exclusively from top-tier bar stock suppliers to ensure consistency and strength in the final product.