Companies operating in automatic turning are benefiting from cutting-edge technologies that enhance production processes, increase precision, and optimize efficiency in the manufacturing of metal components for the B2B sector.

New CNC systems for advanced performance

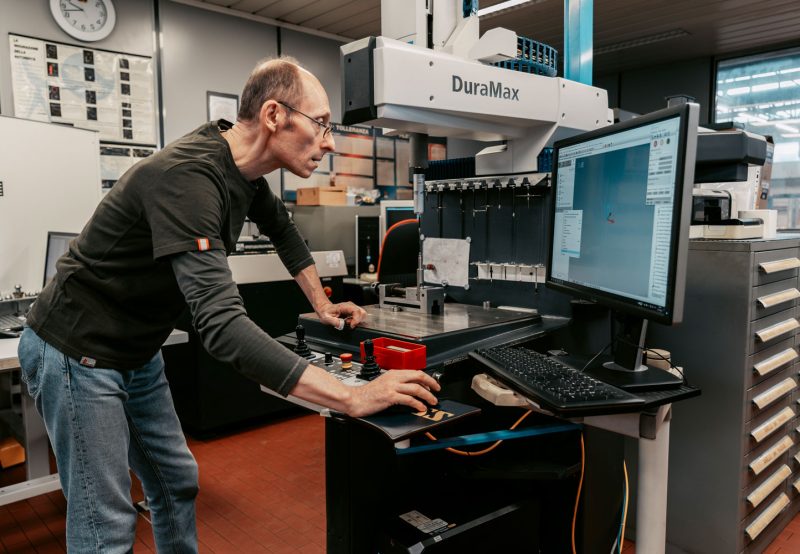

Automatic turning is undergoing a significant evolution thanks to the latest generation of CNC systems. These increasingly high-performance machines ensure extremely precise machining, even on components with complex geometries.

One of the most noteworthy innovations is the introduction of advanced programming algorithms that reduce setup times and accelerate production. With more intuitive interfaces, operations are managed with greater ease, minimizing errors. Additionally, integrated software allows for detailed simulations before machining, ensuring results that fully comply with customer specifications.

For companies like ours, partnering with businesses in the automotive, electronics, or precision mechanics sectors, adopting automated turning machines provides a competitive advantage. These systems ensure highly reliable processes that meet the most stringent industry standards while simultaneously reducing operational costs.

Advanced automation for optimized production cycles

Another rapidly growing area in automatic turning is advanced automation. Machinery is increasingly integrated with robotic systems for loading and unloading operations, ensuring uninterrupted production cycles and higher operational speed.

These solutions not only reduce processing times but also improve the quality of the finished product. Collaborative robots, or cobots, are designed to work safely alongside operators, enhancing operational efficiency and allowing companies to respond quickly to market demands.

Another crucial aspect is the ability to customize production without compromising speed: modern automatic turning systems offer flexibility in managing variable batch sizes, from mass production to small, custom-made series. This approach makes the service more versatile and tailored to the specific needs of customers, ultimately increasing their satisfaction.

For companies requiring technically advanced components, choosing partners that embrace these innovations means accessing high-quality products and reliable, high-performance production processes.

Visit us at our headquarters in San Vendemiano (TV), or contact us now for more information.