Automatic turning for the automotive sector represents a technical challenge that demands precision, innovation, and reliability. Turned components, made from advanced materials such as lightweight alloys, play a crucial role in optimizing performance and reducing vehicle weight.

Automatic turning for automotive: innovation and precision serving efficiency

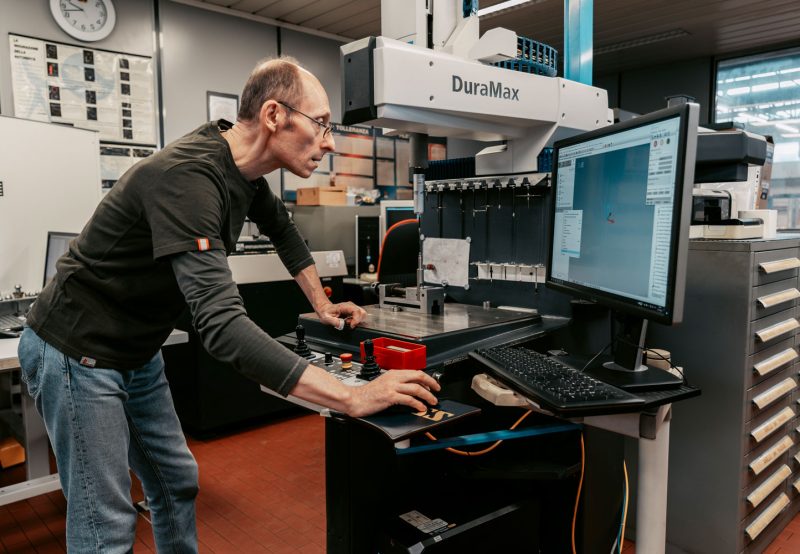

In the automotive industry the use of turned components with industrialized and automated processes is essential to achieving high levels of precision and mechanical performance. Manufacturers require solutions that combine strength, lightness, and reliability to meet the specific needs of modern vehicles, from engines and transmissions to safety systems.

Light alloys, such as aluminum and titanium, are becoming key materials in the production of essential components aimed at reducing weight and enhancing energy efficiency. However, machining these materials requires specialized expertise and advanced technologies. With state-of-the-art CNC machinery, it is possible to achieve flawless surfaces and tight tolerances, ensuring compliance with the strict standards of the automotive industry.

From light alloys to complex systems: reliability in mechanical components

The growing complexity of modern vehicles demands increasingly stringent requirements for mechanical components. Systems like electric drivetrains, automatic transmissions, and active safety devices require flawless production of critical parts. Automatic turning offers tangible advantages, such as the ability to machine complex geometries with micrometric precision and the mass production of high volumes, without compromising quality.

A leading company in automatic turning can support the needs of automotive manufacturers by providing reliable and customizable components. Through a continuous innovation approach, we utilize advanced technologies to process difficult materials and meet customer technical specifications. This not only ensures the quality of the finished product but also optimizes the production chain, which is crucial for the just-in-time nature of the automotive industry.

Automatic turning products for the automotive industry represent the core of the technical innovations reshaping the sector. Overcoming the challenges posed by advanced materials and precision specifications requires expert and reliable partners capable of delivering tailored solutions for every production need. With a company like Sarbo, automotive manufacturers can rely on superior-quality components designed to meet the demands of an ever-evolving industry.