In the automotive sector, continuous innovation demands precision components that can seamlessly transition from prototype to mass production quickly and efficiently. Precision automatic turning, coupled with CNC prototyping and reverse engineering, has become essential to meet this need.

The Value of CNC Prototyping in Automotive Manufacturing

CNC prototyping plays a critical role in creating precision components for the automotive industry. By transforming digital designs into physical prototypes, it enables companies to evaluate functionality and test component performance in real-world conditions before moving to mass production.

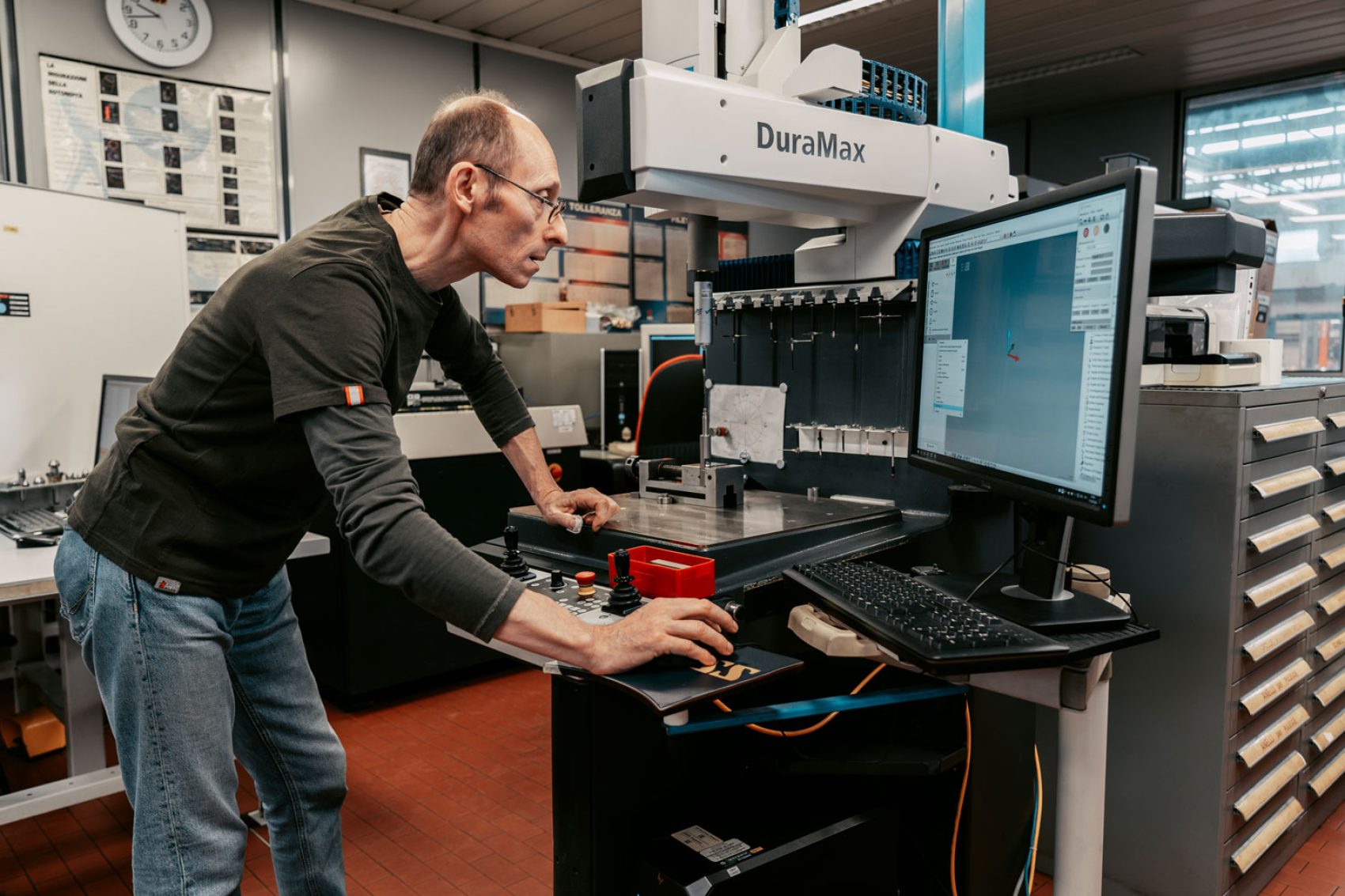

In the automotive sector, where precision is paramount, automatic turning allows the production of complex components with extremely tight tolerances. Utilizing state-of-the-art CNC lathes, such as those in Sarbo’s production lines, ensures the repeatability and consistency that automotive companies require from design through to final production. This approach significantly shortens development times and allows new solutions to be introduced to the market faster and more efficiently.

Reverse Engineering: Bridging Past and Innovation

In the context of the automotive industry, reverse engineering plays a crucial role in restoring or enhancing existing components. This process, based on the precise replication of existing parts, is especially valuable when original production processes are no longer available or need to be modified to meet new requirements.

The capability to perform reverse engineering with the aid of precision turning allows us to offer tailored solutions to our automotive clients. With detailed analysis of a component’s characteristics, CNC prototyping enables the creation of optimized new versions, improving performance and durability. This translates to significant benefits for vehicle manufacturers, who can reduce replacement or maintenance costs without compromising quality and safety.

Precision automatic turning, combined with CNC prototyping and reverse engineering, provides an efficient solution to meet the automotive industry’s complex needs. With advanced technology and established know-how, Sarbo supports clients throughout the entire production process, from prototype to mass production.

Visit us at our headquarters in San Vendemiano (TV) or contact us directly for more information.