Contact us by filling out the form below. One of our representatives will get back to you as soon as possible.

Custom CNC machining services for precision metal parts. Grinding, lapping and treatments

The management of orders with special machining operations, such as grinding, lapping and specific treatments with tight tolerances, is an integral part of our offer. In the sector of precision metal parts machining, choosing a partner that combines advanced expertise and dedicated technologies makes the difference. At Sarbo we offer our customers a complete range of specialized services: from bar turning to precision grinding and lapping, through washing, degreasing, customized packaging and scheduled logistics. Our qualified technicians are at your side to optimize production processes and transform efficient management into a real competitive advantage.

From bar to finished component. The processes in precision metal machining.

At Sarbo, service is not limited to production: it also covers quality control, with 100% dimensional verification for parts requiring extremely tight tolerances. Protective packaging, scheduled logistics and assembly-ready material complete the process, offering a complete package of services for precision turned metal parts.

Each production starts from technical analysis of the customer’s drawing. Sarbo technicians evaluate geometries, materials, tolerances and production volumes, defining the optimal machining cycle. This industrialization phase allows us to reduce waste, optimize time and costs and guarantee repeatability and quality of the final product.

Sarbo collaborates with leading European producers of certified bar material. Bars in brass, free-cutting steel, stainless steel, aluminum or bronze alloys are chosen based on mechanical characteristics and the intended use of the component. Each batch is traced and accompanied by certificates of conformity.

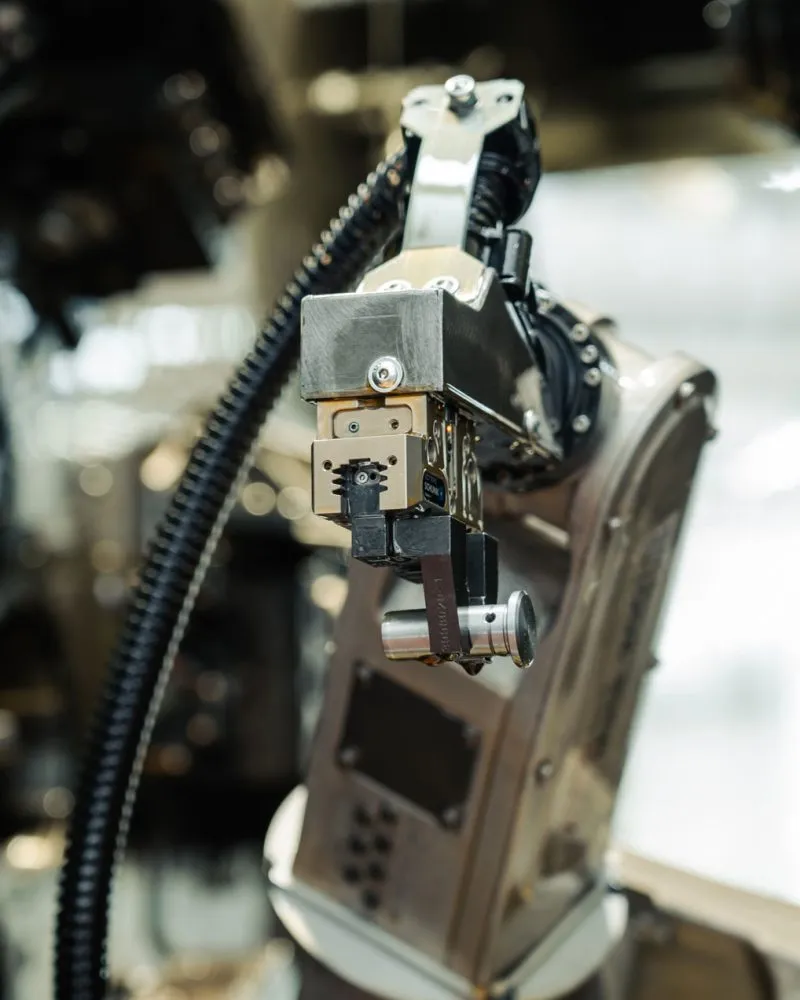

This is the heart of Sarbo’s production process. Thanks to a state-of-the-art machine park, consisting of multi-spindle lathes, twin-spindle lathes, CNC turning centers and sliding headstock lathes, we manufacture complex components with tolerances up to ±0.01 mm. Lean Production logic and OEE (Overall Equipment Effectiveness) monitoring guarantee efficiency and process continuity.

For components requiring even tighter finishes and tolerances, we perform grinding and lapping. These operations allow us to obtain perfectly uniform surfaces, precise couplings and controlled sliding, fundamental in sectors such as medical, hydraulics and pneumatics.

Parts are subjected to vacuum washing with modified alcohols and ultrasonics, a technology that ensures complete removal of residues and contaminants. This process is essential to guarantee the cleanliness and technical compliance of components intended for sensitive sectors such as medical and automotive.

In collaboration with qualified partners, Sarbo performs or manages heat treatments (to increase hardness and wear resistance) and surface treatments (zinc plating, nickel plating, anodizing, burnishing, passivation). Each treatment is chosen to improve mechanical strength and component durability.

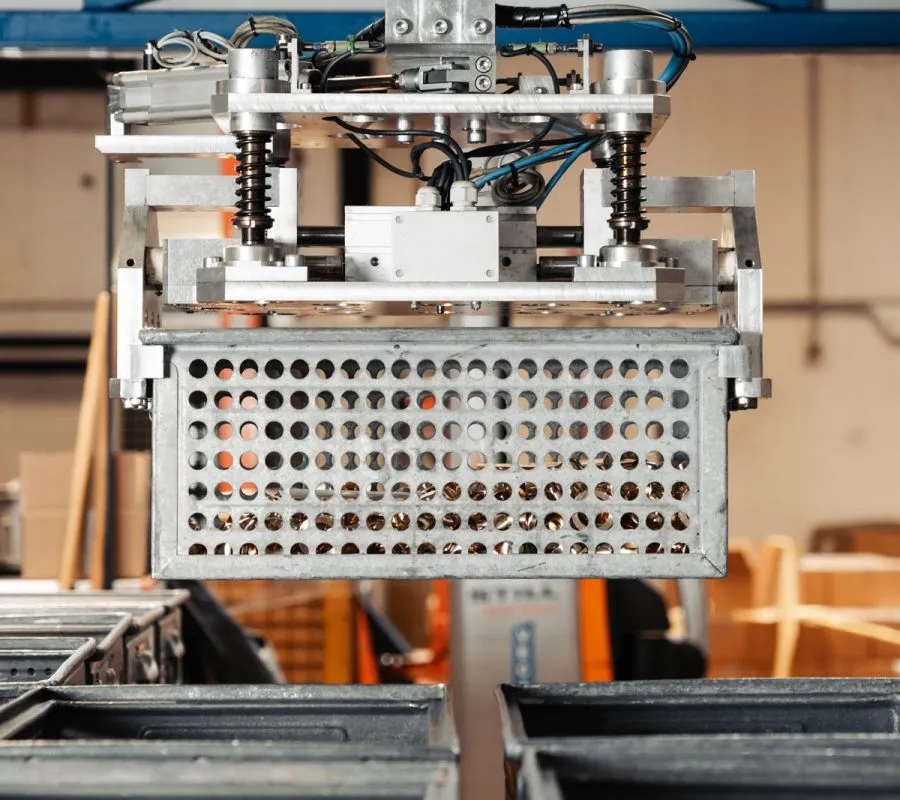

All parts undergo 100% or sampling controls, based on customer specifications. We use three-dimensional CMM measuring machines, optical systems, roughness testers and automatic sorting equipment. Sarbo’s quality system is ISO 9001:2015 certified, and each part is traceable throughout the entire production cycle.

Component packaging is customized based on customer needs: from standard packaging to custom packaging with dedicated labeling, shock protection or technical bagging. The goal is to preserve machined surfaces, guarantee part integrity and facilitate subsequent handling or assembly phases. Thanks to an integrated logistics management system, Sarbo ensures fast delivery times.

Integrated services

Sarbo offers a complete production system: high-cleanliness washing, heat and surface treatments, dimensional controls, packaging and logistics.

Where our metal turned parts find application

Our metal turned parts from bar stock find application in various industrial sectors. The reliability and expertise gained over 50 years are the guarantee of a finished product that meets customer specifications and the highest quality standards.

Sarbo precision CNC machining

Technology, efficiency and control define Sarbo’s production department. Thanks to multi-spindle CNC lathes, twin-spindle lathes and advanced turning centers, we manufacture precision metal turned parts with processes based on Lean Production and OEE system. Constant investments guarantee high performance and certified quality in every machining operation.

Contact us for more information about our services and machining capabilities.

Fill out the form to receive our catalog or request a custom quote for your project.

Back to top

Back to top