Contact us by filling out the form below. One of our representatives will get back to you as soon as possible.

High-cleanliness washing and degreasing for CNC-turned metal parts

The cleaning of small metal parts is a crucial phase in ensuring the quality of the finished component. At Sarbo, we use vacuum washing technology with modified alcohols and ultrasonics, ensuring a high degree of cleanliness and degreasing on every part by completely eliminating oil residues, chips, and contaminants from mechanical machining. This process is fundamental to obtaining perfectly clean components, ready for subsequent treatments, assembly, or use in sectors requiring maximum purity, such as automotive, medical, and pneumatics.

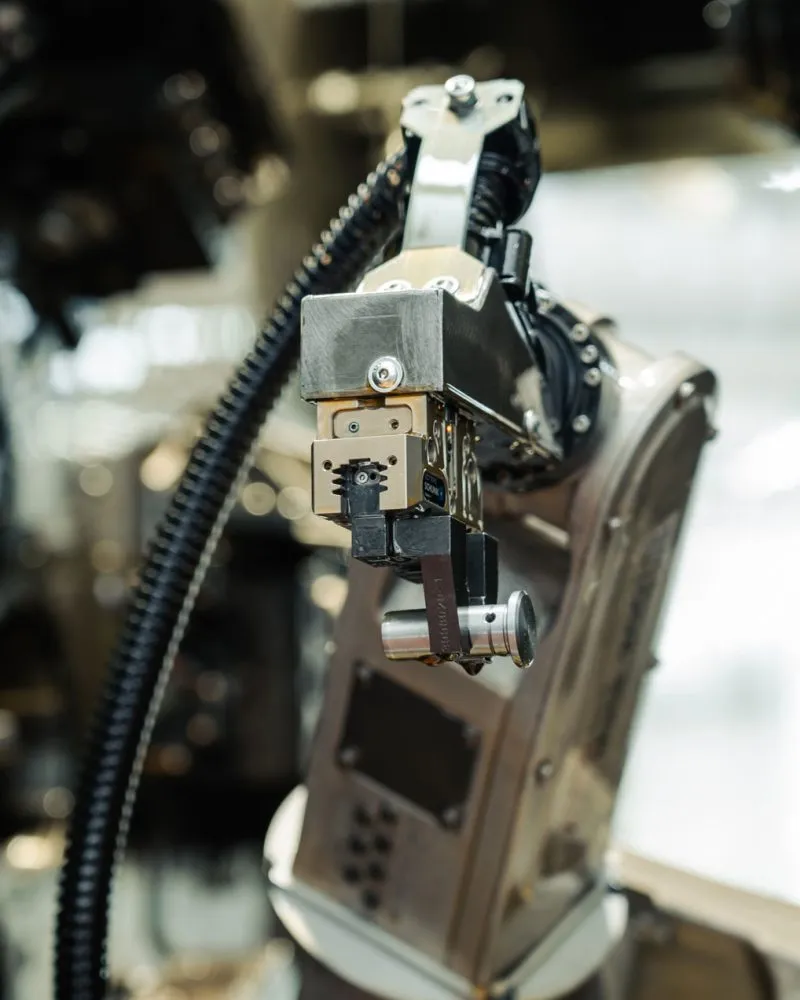

Technology at the service of quality in precision machining

Thanks to modern plants and accurate control of every washing cycle, Sarbo guarantees repeatability, efficiency, and compliance with the strictest standards. The combination of vacuum and ultrasonics allows us to reach even the most complex cavities, preserving the dimensional and surface characteristics of the components. The result is a high-efficiency degreasing process, which improves the quality of the final product and contributes to the durability and reliability of the turned metal parts.

From bar stock to clean , ready-to-use component

At Sarbo, every part stems from an integrated production process ranging from turning to delivery, passing through washing and control phases designed to guarantee components that are perfectly clean, traced, and ready for assembly. Attention to detail, production flow management, and the use of cutting-edge technologies ensure precision, cleanliness, and constant quality in every operation.

Every production run starts with a study of the client’s drawing and specifications. Our technicians define the optimal machining cycle based on materials, tolerances, and required cleanliness needs, guaranteeing efficiency and repeatability.

We use brass, free-cutting steel and stainless steel, aluminum, and bronze bars from qualified suppliers. All materials are accompanied by certificates of conformity and traceability, fundamental for a process that is clean and controlled from the very origin.

Production takes place on latest-generation multi-spindle lathes and CNC machines, capable of manufacturing complex small parts with tolerances up to ±0.01 mm. Every phase is monitored via an OEE system and Lean Production procedures to ensure piece stability and quality.

When required, parts undergo grinding and lapping, which improve surface finish and dimensional precision, ensuring the full efficiency of the subsequent washing and assembly phases.

The heart of the Sarbo process, vacuum washing with modified alcohols and ultrasonics completely removes oils, chips, and contaminants. This treatment guarantees components that are perfectly clean and residue-free, indispensable for applications in the medical, automotive, and pneumatic sectors.

After washing, each batch can undergo heat or surface treatments to improve resistance and durability. Dimensional and quality checks are performed on every part with certified measuring instruments, ensuring compliance with ISO 9001:2015 standards.

Parts are packaged in controlled environments using customized packaging that preserves surface cleanliness. Programmed logistics allow for efficient delivery management, guaranteeing availability and rapid times for every client.

Integrated services

Sarbo offers a complete production system: high-cleanliness washing, heat and surface treatments, dimensional controls, packaging, and logistics.

Where our metal parts are used

Our bar-turned metal parts find application in various industrial sectors. The reliability and expertise gained over 50 years are the guarantee of a finished product that meets client specifications and maximum quality standards.

Precision turning Sarbo

Technology, efficiency, and control define the Sarbo production department. Thanks to multi-spindle and twin-spindle CNC lathes and advanced turning centers, we manufacture precision metal parts with processes based on Lean Production and OEE systems. Constant investments guarantee high performance and certified quality in every operation.

Contact us for more information about our services and machining capabilities.

Fill out the form to receive our catalog or request a custom quote for your project.

Back to top

Back to top