Contact us by filling out the form below. One of our representatives will get back to you as soon as possible.

Integrated warehouse and logistics management for an efficient production process

The warehouse represents a strategic point in Sarbo turning facility’s production system: a space designed to ensure order, safety and control at every storage stage.

Metal bars destined for turning, production tools and finished components are managed internally, with traceability systems that allow monitoring flows and optimizing handling times.

Rational inventory management and integrated order planning maintain production continuity, reduce procurement times and ensure fast, reliable responses to customer needs.

Shipping area and outbound logistics

Finished precision metal parts are packaged in customized packaging and stored in the shipping warehouse, ready for distribution.

Each order is managed according to customer schedules, with delivery planning, dedicated labeling and traceability documentation. The logistics department coordinates transportation with reliable partners, ensuring timely shipments and protected components to the final destination.

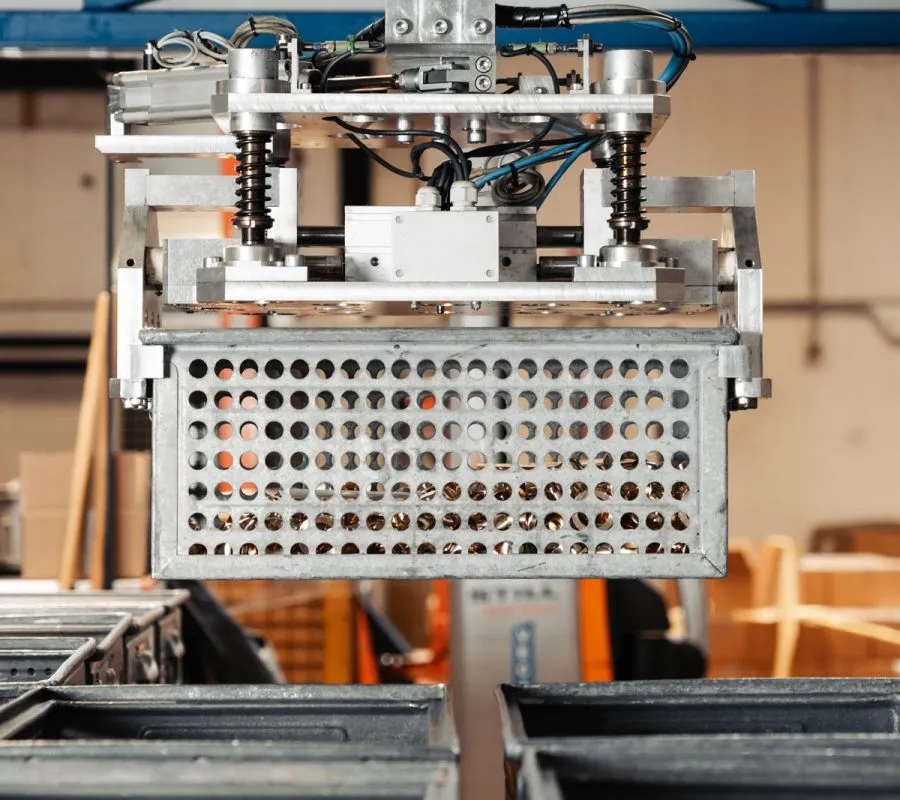

Vertical automatic warehouse for tool storage

The vertical automatic warehouse is dedicated to the management and storage of tools and production components, in an organized and controlled environment.

Thanks to the vertical drawer system, each item is digitally cataloged and easily accessible, reducing search and handling times.

This approach optimizes available space and improves operational safety within the production department.

Raw materials warehouse

Metal bars used for turning are stored in dedicated areas organized by material and diameter.

This visual and coded management system reduces procurement times, ensuring complete traceability and immediate availability of the necessary material for each order. Constant batch monitoring guarantees quality and homogeneity from the origin of the production process.

Integrated services

Sarbo offers a complete production system: high-cleanliness washing, heat and surface treatments, dimensional inspections, packaging and logistics.

Where our precision metal parts find application

Our precision turned metal parts from bar stock find application in various industrial sectors.

The reliability and expertise developed over 50 years are the guarantee of a finished product that meets customer specifications and the highest quality standards.

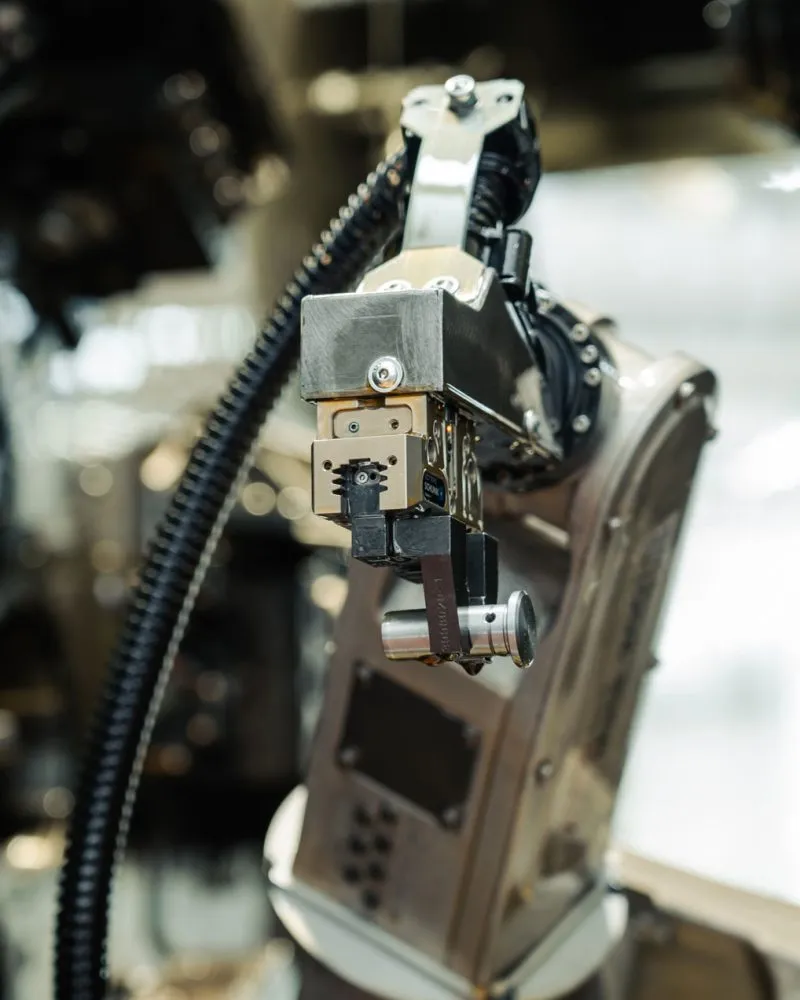

Sarbo precision turning facility

Technology, efficiency and control define Sarbo’s production department. Thanks to multi-spindle CNC lathes, twin-spindle and advanced turning centers, we produce precision metal parts with processes based on Lean Production and OEE system. Constant investments guarantee high performance and certified quality in every machining operation.

Contact us for more information about our services and machining capabilities.

Fill out the form to receive our catalog or request a custom quote for your project.

Back to top

Back to top