Contact us by filling out the form below. One of our representatives will get back to you as soon as possible.

Quality control for precision CNC-turned parts

Quality control is the heart of Sarbo’s reliability.

Every turned component is verified at each stage of the production process, from raw material selection to final testing, to ensure precision, safety and compliance with the most rigorous industrial standards.

Thanks to highly qualified personnel and an ISO 9001:2015 certified system, we ensure consistently high-quality turned metal parts that meet the most stringent specifications required by sectors such as automotive, medical devices, pneumatics and hydraulics.

Integrated quality system

The Sarbo quality system is an environment of technology, control and documentation.

Each phase is recorded and validated, ensuring certified measurements, calibrated instruments and digital process reports. Continuous investments in metrological instruments and technical training maintain high standards of reliability and precision.

The quality process begins with the material. We collaborate with certified suppliers to ensure brass bars, free-cutting and stainless steels, aluminum and bronze alloys compliant with ISO standards.

Each batch is accompanied by certificates of conformity and subjected to chemical-physical and dimensional verification using micrometers, hardness testers and spectrophotometers, ensuring uniformity and homogeneity of the finished product.

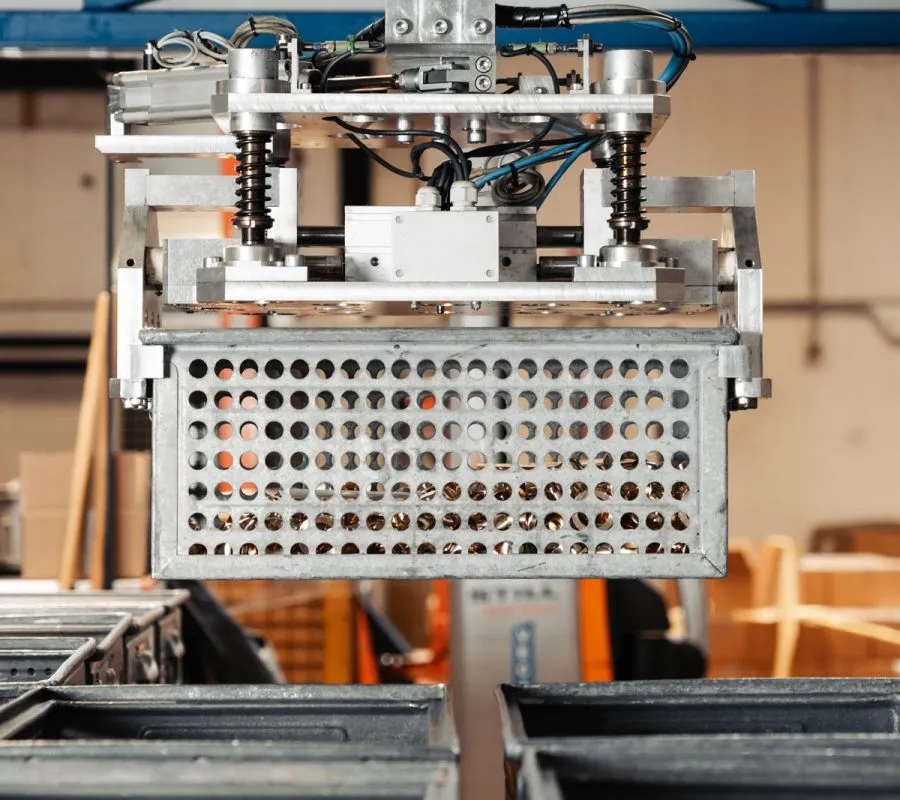

During production, Sarbo implements SPC (Statistical Process Control) systems that constantly monitor critical machining parameters.

Through scheduled sampling and sensors connected to CNC lathes, real-time intervention on any process deviations is possible, maintaining production within specified tolerances. This approach, based on Lean Production and Six Sigma, ensures stability and complete traceability.

Final testing takes place in our climate-controlled metrology lab (20 °C ± 1 °C), a controlled environment ensuring maximum measurement accuracy.

Here, dimensional and geometric inspections are performed using CMM machines, roughness testers and thread gauges to certify the conformity of each batch. Inspections conclude with the release of traceable certificates of conformity, guaranteeing compliance with Sarbo quality standards.

Integrated services

Sarbo offers a complete production system: high-purity cleaning, heat and surface treatments, dimensional inspections, packaging and logistics.

Where our metal parts find application

Our bar-turned metal parts find applications across various industrial sectors. The reliability and expertise developed over 50 years are the guarantee of a finished product that meets specifications and the highest quality standards.

Sarbo precision turning

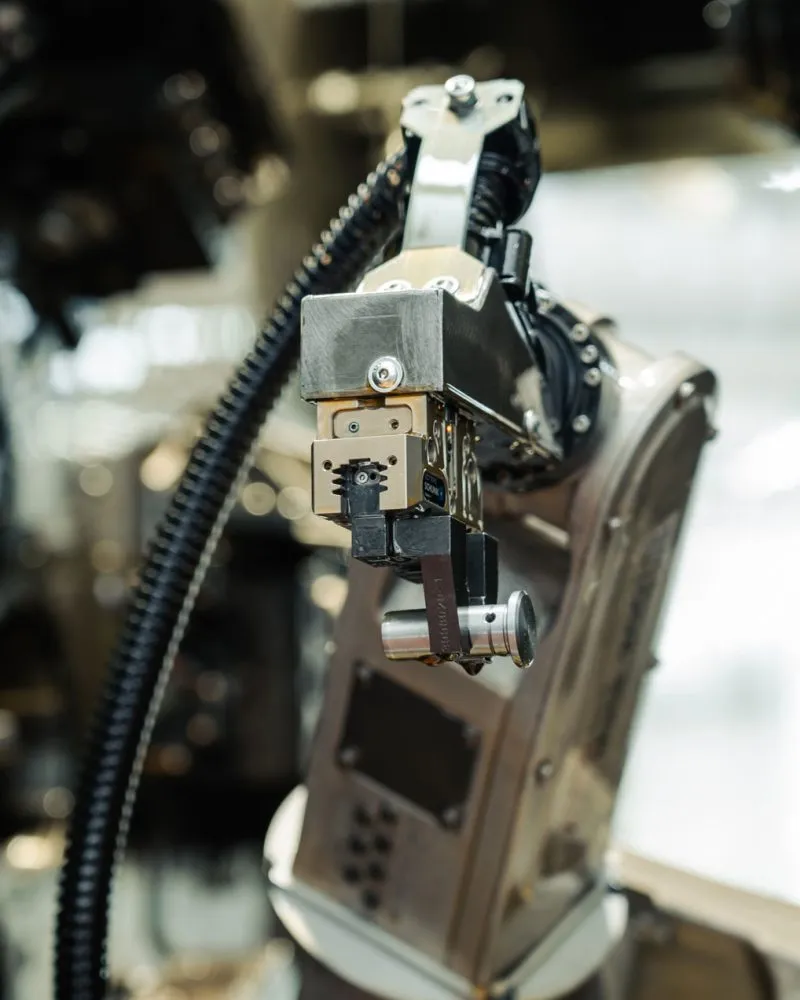

Technology, efficiency and control define the Sarbo production facility. Through multi-spindle CNC lathes, twin-spindle lathes and advanced turning centers, we manufacture precision metal parts using processes based on Lean Production and OEE systems. Continuous investments guarantee high performance and certified quality in every machining operation.

Contact us for more information about our services and machining capabilities.

Fill out the form to receive our catalog or request a custom quote for your project.

Back to top

Back to top