Contact us by filling out the form below. One of our representatives will get back to you as soon as possible.

Heat and galvanic treatments for precision metal parts

At Sarbo, heat and surface treatments represent the final phase of our production process and contribute to improving performance, strength and durability of CNC-turned metal parts.

Through collaboration with certified and specialized partners, we can offer a comprehensive range of galvanic and heat treatments designed to meet the most specific requirements of our industrial customers.

Companies increasingly demand components ready for assembly, with optimized mechanical characteristics and high-level aesthetic finishes.

For this reason, Sarbo integrates treatments into its production cycle that make parts stronger, more resistant and more durable over time, ensuring uniformity and compliance with major international standards.

Main treatments available

Heat treatments. Hardening, tempering, case hardening, carbonitriding and stress relieving—processes that increase hardness and dimensional stability of components.

Galvanic and surface treatments. Zinc plating, nickel plating, anodizing, blackening and passivation, which improve corrosion resistance and aesthetic appearance of parts.

All processes are monitored with adhesion, thickness and roughness controls to ensure full compliance with customer specifications.

Each treatment is part of a traceable and certified process that integrates seamlessly with turning, washing and quality control phases.

From bar stock to treated turned component ready for use

The Sarbo process combines technology, control and know-how to deliver turned, treated components ready for final use.

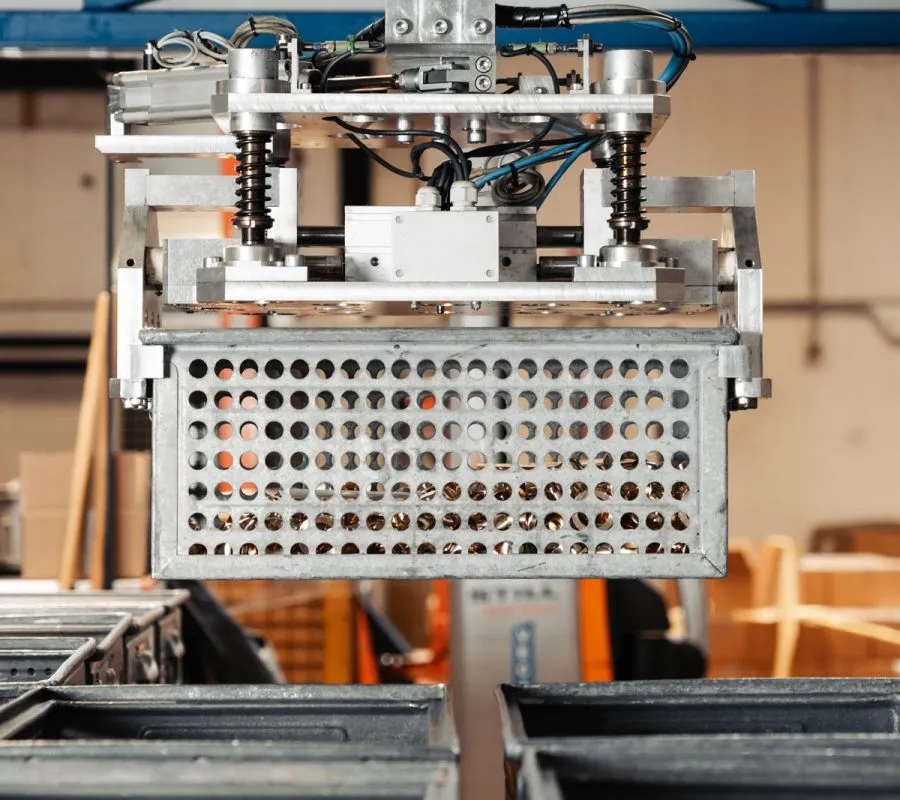

From technical project analysis to raw material selection, from automatic turning to precision machining, washing and treatments, each phase is designed to guarantee high performance and long-term durability. Treated parts are then packaged in protective packaging and managed through automated logistics, ensuring punctuality and production continuity.

Every order begins with evaluation of the technical drawing and customer specifications.

Our technicians define the optimal machining and treatment cycle based on material, required mechanical characteristics and operational conditions of the component.

Sarbo uses brass bars, free-cutting and stainless steels, aluminum and bronze alloys, selected for their structural stability and compatibility with different treatments. Each batch is traced and accompanied by certificates of conformity to ensure maximum reliability throughout the process.

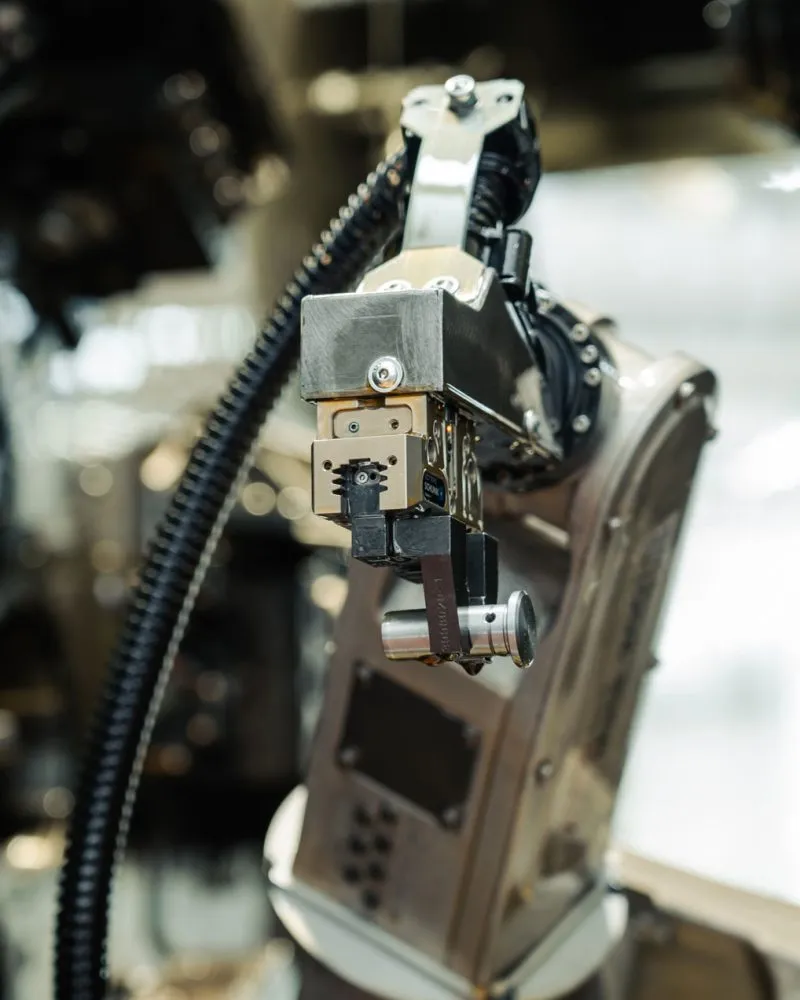

With a fleet of latest-generation multi-spindle and twin-spindle CNC machines, we manufacture complex components with tight tolerances and controlled surfaces. Adoption of OEE systems and Lean Production ensures continuity and consistent quality.

Parts can be further enhanced with precision grinding and lapping, which optimize surfaces and promote perfect adhesion of subsequent surface or galvanic treatments.

Vacuum washing with modified alcohols and ultrasonics to remove oils, chips and contaminants: perfectly clean and reactive surfaces, an essential condition for adhesion and uniformity of subsequent treatments.

Hardening, tempering, case hardening/nitriding; zinc plating, nickel plating, anodizing, blackening, passivation—managed with certified partners for strength, protection and finish.

After treatments, each component undergoes dimensional inspections, adhesion and roughness checks. The ISO 9001:2015 quality system ensures specification compliance and complete traceability of every batch.

Treated parts are packaged with protective materials to preserve surfaces and maintain treatment integrity. Scheduled logistics and automated warehousing ensure punctual deliveries and production continuity.

Integrated services

Sarbo offers a complete production system: high-purity cleaning, heat and surface treatments, dimensional inspections, packaging and logistics.

Applications for our metal parts

Our bar-turned metal parts find applications across various industrial sectors. The reliability and expertise developed over 50 years are the guarantee of a finished product that meets specifications and the highest quality standards.

Sarbo precision turning

Technology, efficiency and control define the Sarbo production facility. Through multi-spindle CNC lathes, twin-spindle lathes and advanced turning centers, we manufacture precision metal parts using processes based on Lean Production and OEE systems. Continuous investments guarantee high performance and certified quality in every machining operation.

Contact us for more information about our services and machining capabilities.

Fill out the form to receive our catalog or request a custom quote for your project.

Back to top

Back to top