Contact us by filling out the form below. One of our representatives will get back to you as soon as possible.

Packaging and Shipping of Precision Metal Components

Packaging represents the final step in a production process controlled in every detail. At Sarbo, each component is packaged according to customer specifications, selecting protective materials and customized solutions to preserve surface quality and facilitate handling.

From shaped containers for delicate components to reinforced industrial packaging, every shipment is tracked and managed in coordination with our logistics department.

Thanks to precise organization and integrated warehouse planning, we guarantee fast delivery times, transport safety and production continuity for every order.

From metal bar to packaged component ready for delivery

At Sarbo, every precision metal component follows an integrated production path that combines technology, precision and control. From raw material selection to final packaging, every phase is managed with attention to detail and complete traceability, to guarantee compliant, clean components ready for use.

A fluid and coordinated process that ensures production continuity and certain delivery times.

Every project begins with technical study of the customer’s drawing. Our specialists define the optimal production cycle, planning times, materials and logistics flows to integrate production and warehouse management.

Metal bars in brass, steel or aluminum come from qualified and certified suppliers. Each batch is tracked to guarantee uniformity and reliability throughout the entire production process.

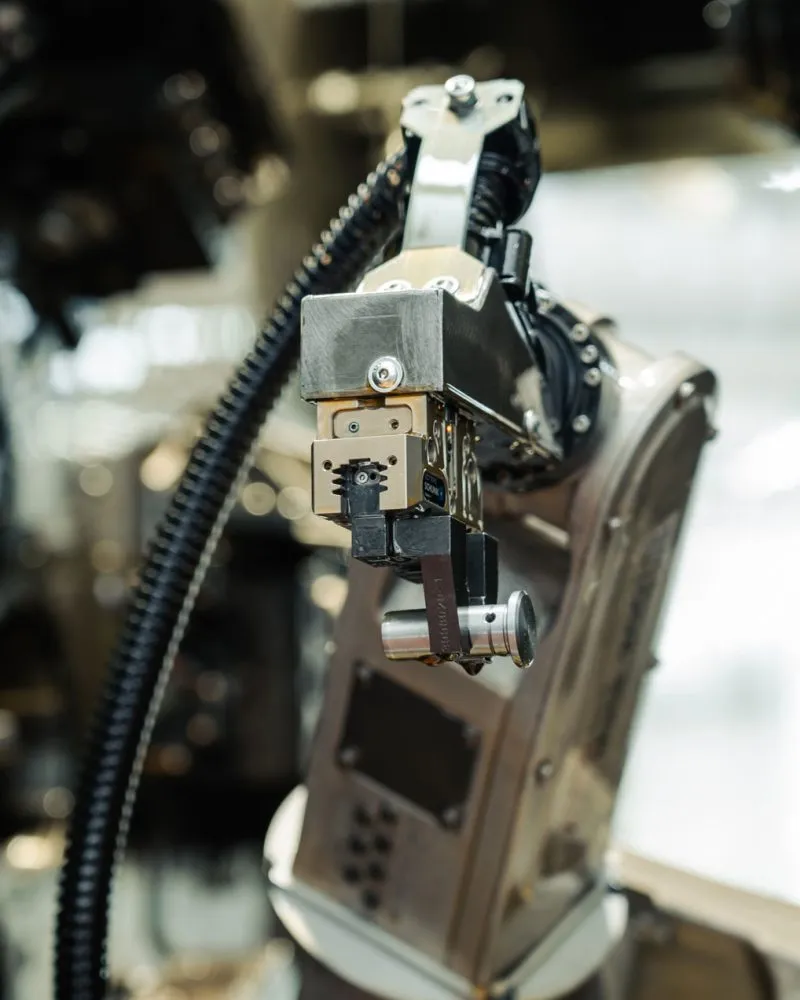

Production takes place on latest-generation multi-spindle and CNC lathes. Operations are monitored in real time with OEE systems and Lean procedures, ensuring continuity, repeatability and consistent quality.

If required, components undergo grinding, lapping and heat or surface treatments to improve their mechanical performance and durability over time.

Each batch is washed and degreased with ultrasonic vacuum technologies to remove impurities and machining residues. ISO 9001:2015 certified quality control ensures full compliance with required technical and dimensional specifications.

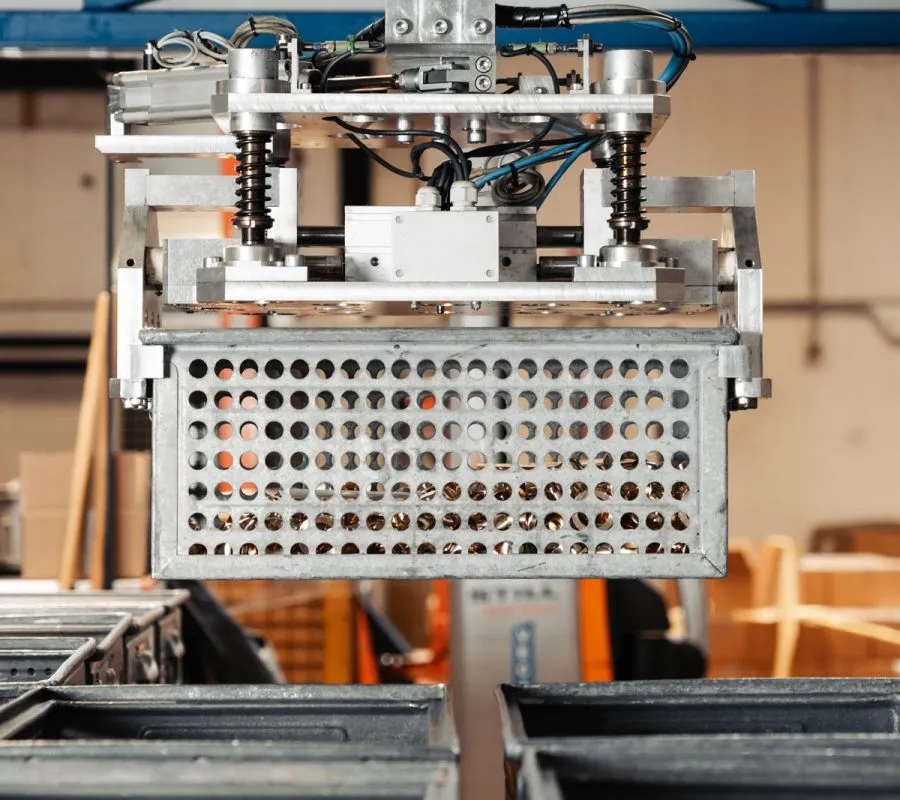

Components are packaged in trays, boxes or custom industrial packaging, designed to preserve surface cleanliness and integrity.

Each package is labeled and tracked to facilitate identification and assembly.

From the Sarbo warehouse, precision components are managed with integrated logistics, ready for delivery according to timelines agreed with the customer. Efficient inventory management guarantees constant availability and punctual shipments.

Integrated services

Sarbo offers a complete production system: high-cleanliness washing, heat and surface treatments, dimensional controls, packaging and logistics.

Where our precision metal components find application

Our precision turned metal components from bar stock find application in various industrial sectors. The reliability and expertise gained over 50 years are the guarantee of a finished product that meets customer specifications and the highest quality standards.

Sarbo precision turning

Technology, efficiency and control define the Sarbo production department. Thanks to multi-spindle CNC lathes, twin-spindle lathes and advanced turning centers, we produce precision metal components with processes based on Lean Production and OEE system. Constant investments guarantee high performance and certified quality in every operation.

Contact us for more information about our services and machining capabilities.

Fill out the form to receive our catalog or request a custom quote for your project.

Back to top

Back to top