Contact us by filling out the form below. One of our representatives will get back to you as soon as possible.

We industrialize your needs

Sarbo stands out for its ability to optimize every phase of the production cycle, offering customized and highly specialized solutions to meet industrial needs.

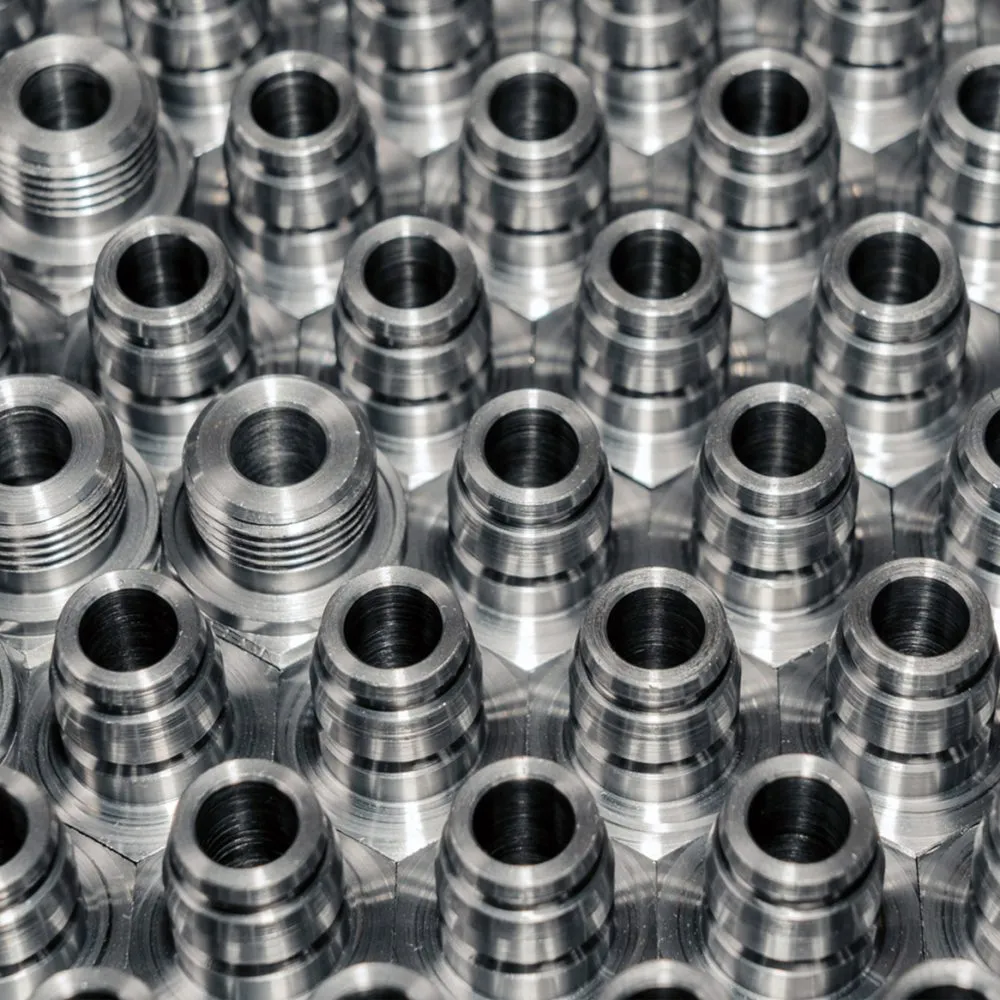

Thanks to our established experience and the use of the most modern CNC technologies , we are able to meet all market demands, which are constantly evolving. Our commitment to efficiency and quality allows us to guarantee precision CNC turned parts that meet specific requirements and industry standards.

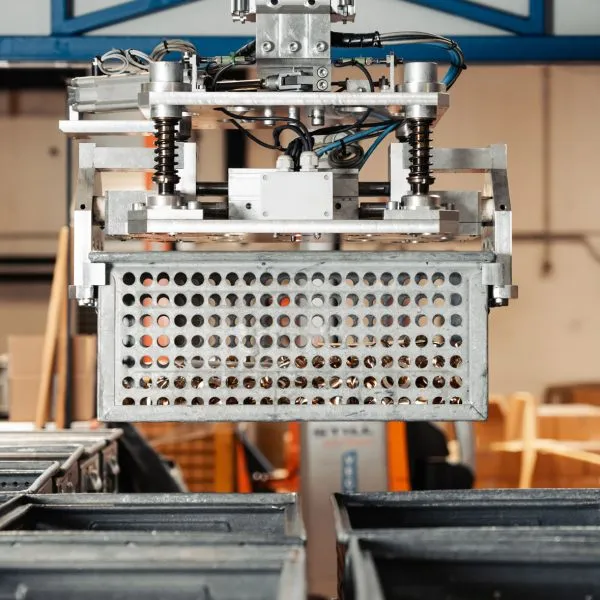

Our integrated approach ensures that every phase, from washing to logistics, is managed with meticulous attention to quality, optimizing processes and reducing costs for our customers. Customized packaging, scheduled storage and real-time transportation are the strengths that make us the ideal partner for industry.

Advanced mechanical machining with automatic turning

Sarbo specializes in automatic turning and contract mechanical machining, with CNC turning solutions and precision mechanical turning for the main industrial sectors.

Thanks to our advanced machine park, which includes automatic multi-spindle lathes, CNC twin-spindle lathes, CNC turning centers, sliding headstock lathes and the new Multisprint 36 multi-spindle lathe, we are able to handle even the most complex requirements. This cutting-edge technology enables us to guarantee perfect components, compliant with customer specifications and the highest quality standards, ensuring optimized production solutions for every type of machining.

Technology and know-how at the service of the customer

Highly qualified personnel operate according to modern and certified procedures. Sarbo is able to manage orders with special machining operations including grinding and lapping.

The most modern vacuum technologies with modified alcohols and ultrasonics enable us to treat and wash parts with a high degree of cleanliness and degreasing.

In addition, all types of heat or surface treatments are possible with the assistance of our selected partners.

Where our metal turned parts are used

Sarbo CNC turned parts manufacturers supply components used in sectors requiring high precision and reliability. In the automotive sector, our components undergo rigorous quality controls, while in the medical sector we guarantee a high degree of cleanliness and precision. For appliances, we offer solutions optimized in terms of both performance and design. Our machining for pneumatics ensures reliable components, while in the hydraulics field we manufacture products with high productivity and compliance with rigorous standards.

Certified quality

Efficiency and effectiveness are our objectives. Our technologically advanced equipment is constantly updated and monitored through the OEE system (Overall Equipment Effectiveness). Production processes follow Lean Production and Six Sigma logic to optimize quality and costs. Product quality, which has always been the company’s strength, is guaranteed by standardized operating methods and advanced measuring instruments, in compliance with ISO 9001:2015 certification.

Back to top

Back to top