Sarbo implements Statistical Process Control (SPC) systems to monitor quality in real-time during production. Through continuous monitoring of critical parameters, we immediately identify any process drift, intervening preventively to maintain production within required specifications.

Excellence standards in quality control for precision automatic turning

CNC quality control of mechanical products has always been the cornerstone of our automatic turning service. Our highly qualified personnel operate according to modern and certified procedures.

Our conformity verification process for turned metal parts from bar stock guarantees precision, safety and functionality of components across all application fields and sectors.

Meticulous process checks ensure high quality standards, that meet even the most restrictive sector requirements, ensuring excellent metal parts that comply with the most rigorous specifications.

We focus on quality because it best meets our customers’ needs: our turned bar parts are manufactured specifically to client drawings, our materials are of excellent quality and help us, with their characteristics, produce even better components.

Our quality standards have been high for over 50 years, because we firmly believe that quality must be at the center of production processes.

Metrology room

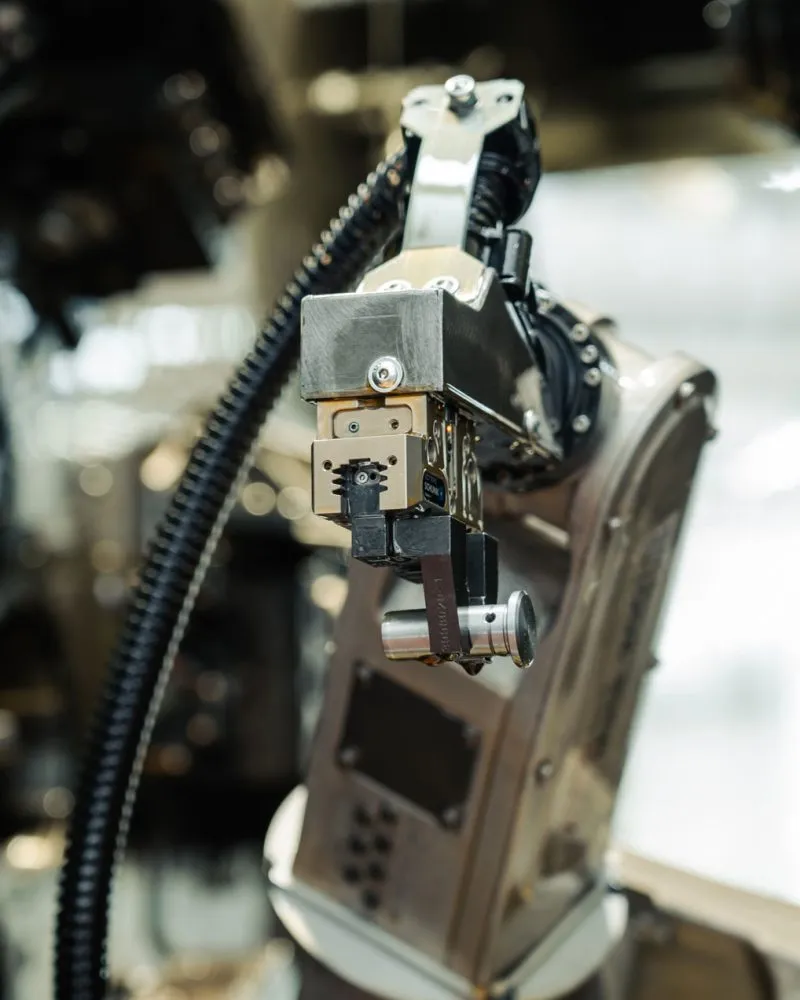

SPC process controls

Certified measurements

Integrated CNC quality control system for metal parts

CNC quality control begins with exclusive collaboration with major bar material manufacturers, guaranteeing high standards of homogeneity and resistance in the finished product.

Our qualified industrial metrology operators rigorously verify every delivery of brass, free-cutting and stainless steels, alloy steels, aluminum alloys and bronze using digital calipers, micrometers, durometers and spectrophotometers for chemical-physical analysis.

All material arrives with certificates of conformity attesting the necessary characteristics, while our long-established trusted suppliers ensure easily machinable raw materials according to ISO 9001:2015 standards for supplier qualification.

During automatic turning, our CNC quality control implements continuous monitoring through Statistical Process Control with scheduled statistical sampling. Specialized technicians use portable CMM machines, profile projectors and integrated SPC software to verify dimensional tolerances in real-time on each batch of metal parts.

The system automatically detects any process drift through sensors connected to automatic lathes, allowing immediate corrective interventions. This approach, based on Lean Production and Six Sigma protocols, guarantees production stability and continuous conformity documentation according to advanced industrial quality methodologies.

The conclusive CNC quality check takes place in our metrology room maintained at constant temperature and humidity (20°C ± 1°C) to ensure maximum measurement precision.

Certified metrology specialists perform complete dimensional and geometric controls using coordinate measuring machines (CMM), surface finish roughness testers, threaded plugs and rings for functional verification.

Each batch of metal parts undergoes sector-specific tests (automotive, medical, pneumatic, hydraulic) with dedicated test benches, concluding with the issuance of traceable certificates of conformity that document every phase from raw material to finished product according to ISO 9001:2015 certification.

High-quality raw materials

Sarbo collaborates with major bar material manufacturers, ensuring high standards of homogeneity and resistance in the finished product for customers. We work with brass alloys, free-cutting and stainless steels, alloy steels, aluminum alloys and bronze.

Integrated quality system

Our equipment is technologically advanced and constantly updated with substantial annual investments to ensure maximum precision and production reliability.

Our climate-controlled metrology room represents the heart of Sarbo’s quality control. Maintained at constant temperature and humidity (20°C ± 1°C), it guarantees ideal conditions for performing high-precision measurements on turned metal parts from bar stock.

Each production batch is accompanied by certificates of conformity attesting compliance with required specifications. Our certified measurements follow international standards and are performed with calibrated instruments according to ISO procedures.

CNC automatic turning

Our facilities are technologically advanced and constantly updated with substantial annual investments.

Where our metal parts find application

Contact us for more information about our services and machining capabilities.

Fill out the form to receive our catalog or request a custom quote for your project.

Do you want to stay updated on all the latest news?

Subscribe to our newsletter to receive updates and news

Back to top

Back to top